Dry Lubricant Coating MCF COATING

Realizing the fluid lubrication property

specific to oil and grease

by dry film

Excellent lubricant coating and 100% fluorine coating. This coating is achieved by the Okitsumo’s unique dry process coating technology.

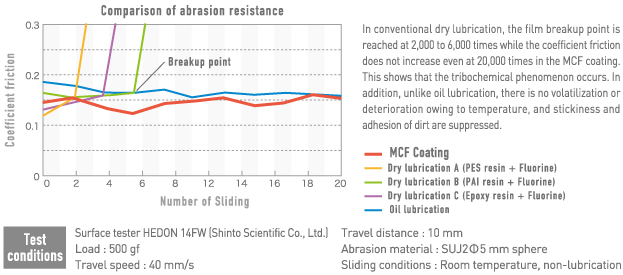

- Feature Surprising abrasion resistance with non-lubrication (oil-free)

- Feature No gas generation *at 250ºC or less

- Feature Applicable to resin

- Feature Heat resistance of 250ºC

Dry lubrication displacing oil lubrication

- Dry lubrication is a film formed by combining a solid lubricant agent of fluorine and molybdenum with resin and is called a dry lubricating film.

- The film is widely used in a vacuum or high-temperature atmosphere where liquid lubrication by oil cannot be used or for parts that are sensitive to sticking.

Advantages of dry lubricating film

- Functionality realized even under high-temperature, low-temperature, or vacuum state

- Maintenance-free providing reduction of working hours

- Oil-less lubrication realizing non-adhesive clean workability

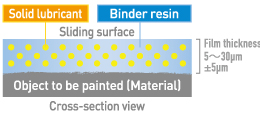

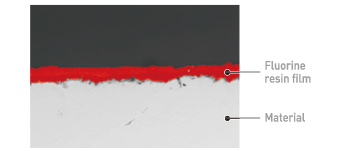

■ Mechanism of MCF Coating

Okitsumo’s unique dry process coating technology has realized a 100% fluorine resin film.Formation of binder-less 100% fluorine resin film will deliver the best possible lubrication performance specific to fluorine.

■ Abrasion resistance of MFC coating is 3.3 times as much as that of conventional dry lubricant

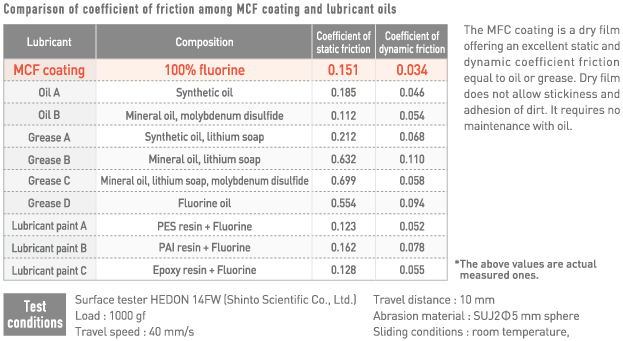

■ Coefficients of static and dynamic frictions achieved in MCF

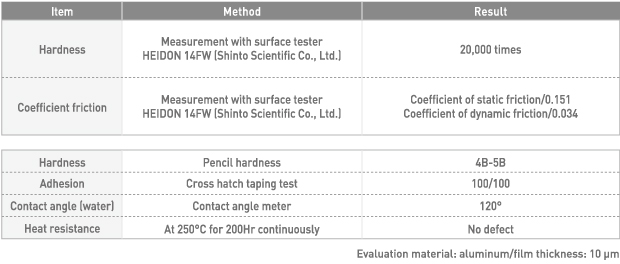

■ Basic Performance of MCF Coating

Expanding applications and capabilities.

- Bearing parts

- Ball bearing

- Relay switch

- Gear

- Door lock

- Various types of gears

Product search

Product search

Category Search

-

Search by product type

-

Search by application field

- Product lineup

- TDS