Heat resistant solder resist ink(For FPC)

TAINEX HRS-1-5G Green Alkaline development typeUnder

development

Flexible as well as heat-enduring

This is an ink dedicated for use with flexible substrates due to its superb durability against bending.

-

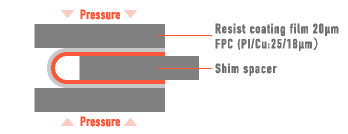

Feature flexibility:No crack was detected after continued heating at 150℃for 1000 hours under the bending state

(curvature radius R = 0.1). - Feature Warp:Warping of substrates after heating will be smaller than general products.

Feature flexibility

Continuously heating the inflected product.

-Inflection: curvature radius R=0.1

-Heating: continuous heating at 150 deg. C

The general resistor ink substrate revealed cracks after heating at 150°C for 24 hours under the bending state, but HRS-1-5G had no cracks even after heating at 150°C for 1000 hours.

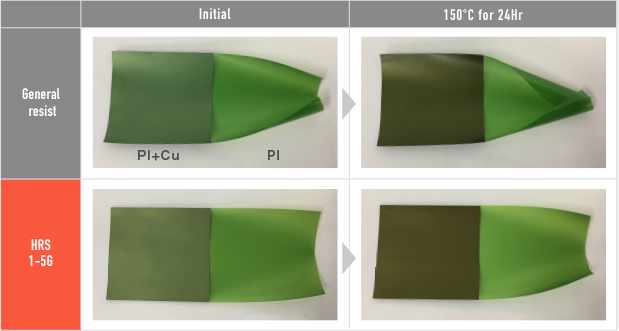

Feature Warp

Heating at 150℃ for 24Hr

These pictures reveal that the substrate warping is smaller than the general resist after heating at 150°C for 24 hours.

■Coating film performance

| Item | Test method |

HRS-1-5G (Under development) |

|---|---|---|

| Hardness | JIS K5600-5-4 | H |

| Adhesion | JIS K5600-5-6 | Category 0 |

| Bending resistance | JIS K5600-5-1 180°inflection | OK(R0.1) |

| Solvent resistance | Isopropyl alcohol, 5Min immersion at room temp. | OK |

| Acetone, 5Min immersion at room temp. | OK | |

| Acid resistance | 10% sulfuric ,30 Min immersion at room temp. | OK |

| Alkaline resistance | 5% sodium hydrate, 5 Min immersion at room temp. | OK |

| Solder resistance | JIS C6471 260 deg.C for 20 Sec. | OK |

| Gold plating resistance |

Electroless nickel gold plating process (Ni:3μm、Au:0.05μm) |

OK |

| PCT | 121 deg. C for 9 Hr | OK |

| Light reflection rate |

Measurement by colorimeter (SCI system) (Measurement range: 360-740nm) |

- |

| Radiation rate |

Measurement by heat radiation rate meter (Range: 3~30μm) |

80% |

| Combustibleness | UL94 standard | VTM-0 eq. |

| Total amount of chlorine | Calculated from material used (calculated value) | 60.6ppm |

■Electronic characteristics

| Item | Test method |

HRS-1-5G (Under development) |

|---|---|---|

| Insulation resistance | Initial value | 9.0×1012Ω |

| Moisture resistance test based on JIS C5016-9-4,followed by insulation resistance value measurement. | 1.3×1013Ω | |

| Surface resistanse | JIS C6481-5-10 | 1.0×1013Ω |

| Volume resistivity | JIS C6481-5-9 | 1.0×1014Ω・cm |

| Voltage resistance |

500V×1Min energization (Measured film thickness 20μm) |

OK |

| Relative permittivity | JIS C6481(1MHz) | 4.9 |

| Dielectric tangent | JIS C6481(1MHz) | 0.08 |

*The results above show reference values, not standard values.