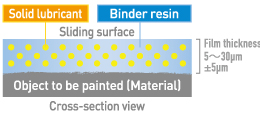

Ultra Precision Lubricative Coating UPL COATING

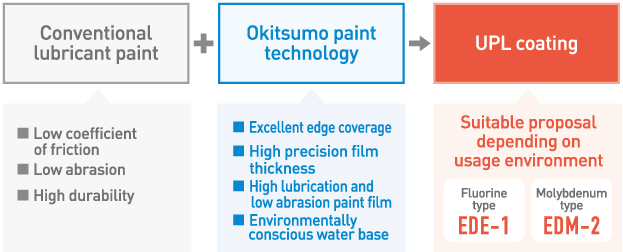

Uniform lubricative paint film at any section

Applicable materials are all metals, and it is possible to uniformly paint complex shapes and tiny parts. The paint creates a low coefficient friction film that is excellent in abrasion resistance.

- Feature Excellent edge coverage

- Feature Advanced film-thickness control technology

- Feature Paint film with high lubrication and low abrasion

- Feature Environmentally conscious water based paint

- ● UPL coating is available in the fluorine type (EDE-1) and molybdenum type (EDM-2). We can make a proposal suitable for the usage environment.

Dry lubrication displacing oil lubrication

Dry lubrication is a film formed by combining a solid lubricant agent of fluorine and molybdenum with resin called a dry lubricating film. Dry lubrication is widely used in vacuum or high-temperature atmospheres where liquid lubrication by oil cannot be used or for parts that are sensitive to sticking.

Advantages of dry lubricating film

- Functionality realized even under high-temperature, low-temperature, or vacuum state

- Maintenance-free providing reduction of working hours

- Oil-less lubrication realizing non-adhesive clean workability

■ A higher level of quality by UPL coating

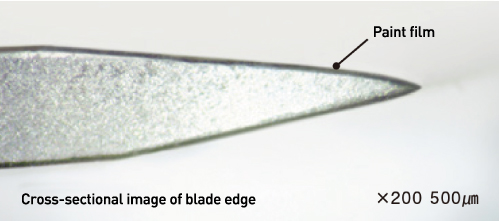

■ Excellent Edge Coverage

Even a sharp blade edge is painted uniformly.

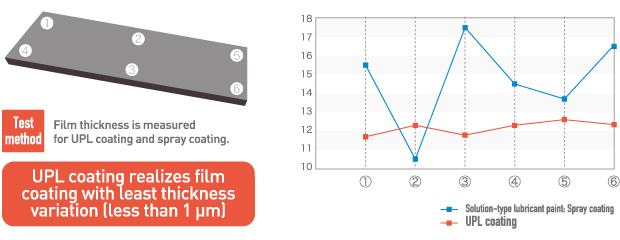

■ Advanced Film-Thickness Control Technology

Film thickness measurement results (actual measured values)

Film thickness was measured for UPL coating and spray coating.

UPL coating realizes film coating with least thickness variation (less than 1 μm).

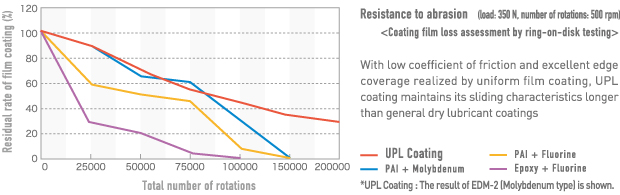

■ Excellent resistance of UPL coating to abrasion

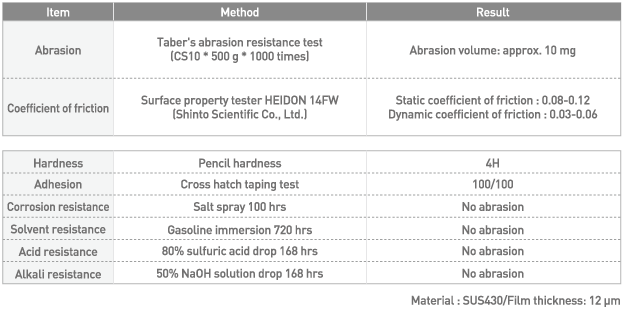

■ Basic performance of UPL coating (fluorine type)

Expanding applications and capabilities.

Product search

Product search

Category Search

-

Search by product type

-

Search by application field

- Product lineup

- TDS